Power take-offs transform your Scania truck into a working platform for multiple industries. Choosing the correct Scania PTO demands consideration of gearbox specifications, operational needs and compatible hydraulic components to maximise performance across tipping, loading and material handling tasks.

Understanding Scania gearbox compatibility

Scania PTOs must match your gearbox model. GR 900 gearboxes fitted to 3 Series and 4 Series trucks use right-side mounting PTOs with pneumatic control systems. Your 900 series gearbox works with 1/0.78 ratio units, generating 245 Nm torque output.

GR/GRS 875 and 895 P and R Series truck gearboxes require rear-mounted PTO units. These transmissions accept 1:1 ratio configurations and deliver a 436 Nm torque capacity suitable for demanding applications.

R Series trucks with GR/GRS 905 and 925 gearboxes need dedicated rear-mounted PTOs explicitly designed for these transmission types. Similarly, GRSO 905 and 925 gearboxes require compatible units maintaining consistent 436 Nm torque ratings.

Related: What kind of hydraulic pump do I need?

Standard vs high-output configurations

Standard PTOs handle daily tipping operations without strain, while high-torque variants support more demanding applications.

Your operating cycle determines which configuration suits your requirements, with basic tipping operations working effectively using standard units.

Walking floor systems benefit from pneumatic-controlled PTOs generating higher torque output. The 436 Nm rated units prevent premature wear during extended operational cycles and provide consistent hydraulic pressure throughout demanding jobs.

Pump compatibility for Scania PTOs

Right-side mounted PTOs connect with 3-bolt UNI hydraulic pumps, while rear-mounted units accept 3-bolt UNI and 4-bolt ISO configurations. When matched with appropriate pumps rated for expected flow requirements, your hydraulic system performs optimally.

Bent-axis piston pumps paired with high-torque PTOs suit demanding applications like walking floors and large tipping bodies. Standard gear pumps in 27L and 34L capacities handle routine tipping operations with sufficient flow rates for typical cycle times.

Related: A Guide to Iveco PTOs

Cab controls and management systems

Pneumatic control systems activate your PTO via cab-mounted switches. Solenoid valves enable engagement without leaving your cab, with 2-way and 3-way configurations available depending on your hydraulic circuit requirements.

Manual and Opticruise gearboxes accept identical PTO units across Scania ranges, maintaining consistent mounting patterns. Your gearbox type, rather than age or model designation, determines fitting requirements.

Related: Tipping cab controller and PTO switch guide

Essential components for complete installations

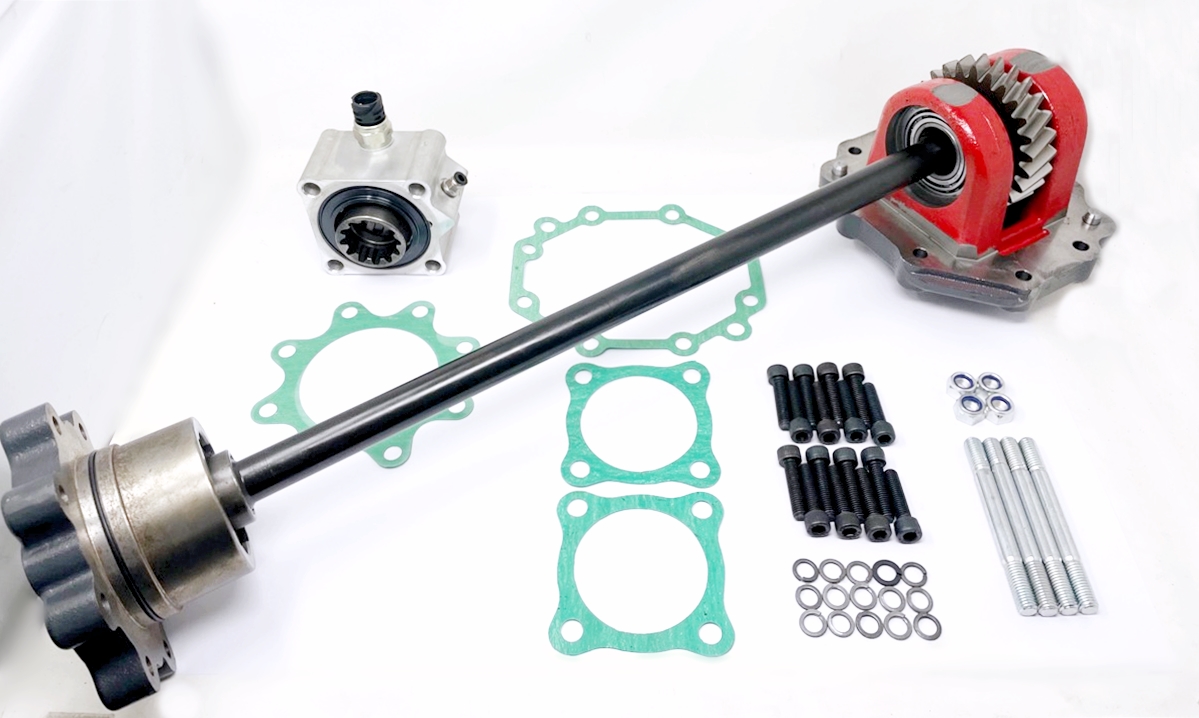

Complete PTO kits include mounting gaskets and fixtures for proper installation. Your kit contains essential connection hardware to prevent leakage during operation, and pneumatic control systems provide activation signals.

Aluminium tanks in 45-190 litre capacities supply sufficient oil volume for demanding applications while providing adequate cooling capacity.

Contact our sales team

We provide tailored quotations and availability information on all PTO components. We also have much more stock than is displayed on our website, and we can source parts for you.

Call 01262 601600 for assistance today.

Further reading: A guide to Mercedes PTOs

[…] A guide to Scania PTOs […]