Walking floor trailers need dedicated hydraulic systems that handle continuous bidirectional operation. Our Mercedes twin-line wet kit covers Actros and Arocs models from Euro 3 through Euro 6, fitting twelve different Mercedes gearbox variants.

The kit delivers 108 litres per 1000 RPM through a bent-axis piston pump rated to 400 bar maximum pressure.

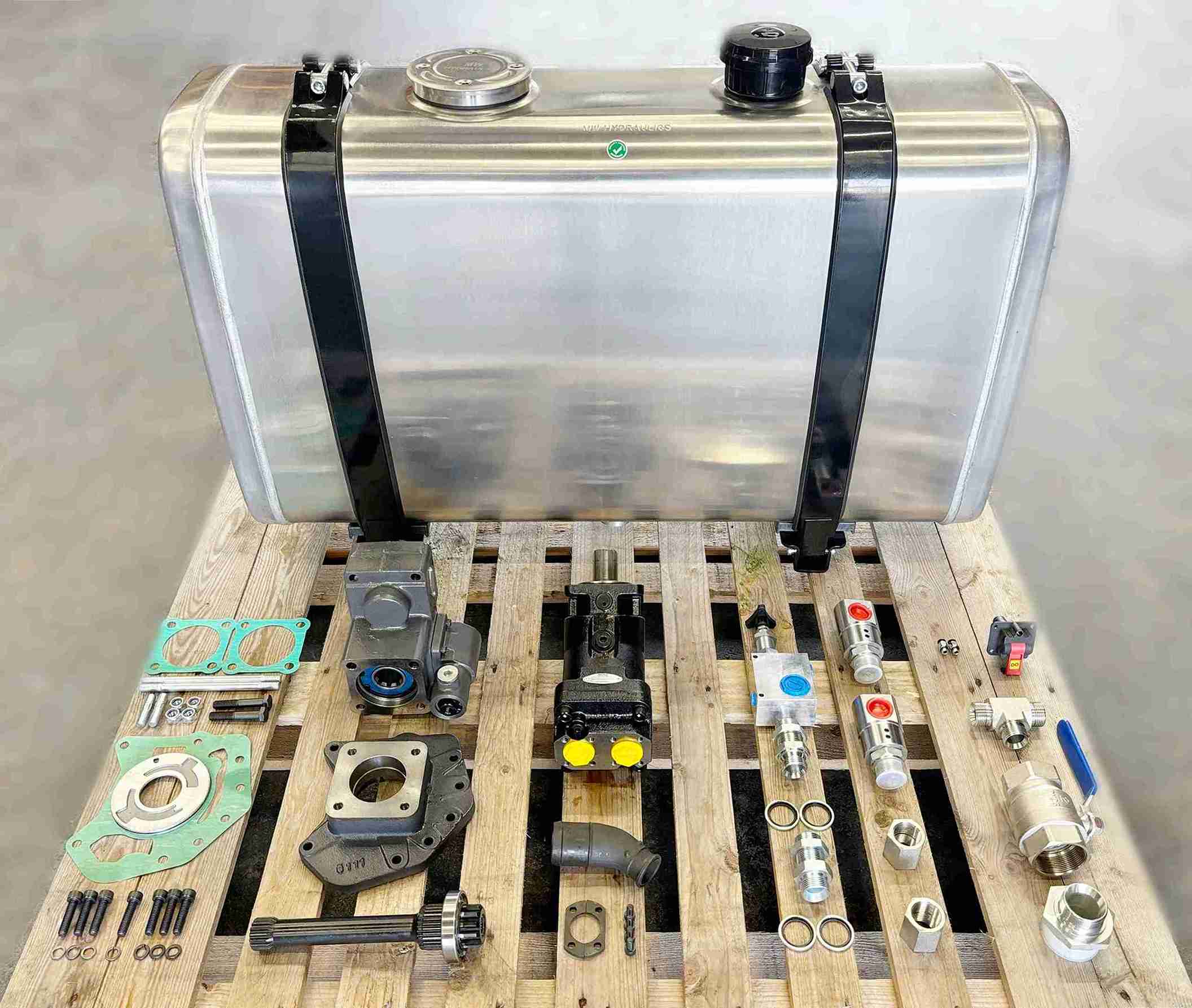

Products in this guide:

Tank configuration

Our kit includes a 200-litre side-mounted aluminium tank, with two return lines entering the tank at different points.

The first runs through the directional valve mounting plate at 1″ BSP female. The second connects via the upper rear suction adapter at 1½” BSP male. Pump feed draws from the lower rear adapter at 2″ BSP male.

Internal filtration uses 25-micron elements with breather strainer caps. Oil level indicators show working fluid without removing caps. Mounting brackets, straps, and rubbers come standard with the tank assembly.

Pump specifications

Hydraulic power comes via a bent-axis piston pump that displaces 108 litres per 1000 RPM at 350 bar working pressure.

Bidirectional rotation suits walking floor operation, where you reverse material flow without changing pump direction. The inlet uses a 1″ BSP split flange with seal and mounting screws. Outlet connection threads at 1″ BSP. Pump weight reaches 16kg installed.

Hose tails come included with the pump assembly. Walking floor systems need secure connections that handle pressure spikes during material movement.

Related: Which applications suit axis pumps?

Pressure control

Inline relief valves adjust from 50 to 380 bar through variable settings. Stainless steel construction with locking nuts prevents pressure drift during operation. Maximum flow capacity reaches 100 litres per minute.

Four port configurations handle different circuit requirements. Inlet and outlet ports manage primary flow. Tank ports provide return routing. Test ports allow pressure monitoring without breaking hydraulic connections.

PTO and engagement

Twin-wheel clutch PTOs mount to the rear of compatible Mercedes gearboxes. Pneumatic control uses air switching at a 5-10 bar pressure range. The 1:1.2 overdrive ratio increases pump speed beyond engine RPM for adequate hydraulic flow.

Torque rating reaches 531 Nm across the operating range. Quill shafts, adapter plates, gaskets, and mounting hardware ship with each PTO assembly. Connectors attach to the pneumatic switch included in the kit.

The air switch handles single-way operation through 1/8″ BSP connections. Walking floors engage the PTO and run continuously during material discharge rather than cycling on and off like tipping operations.

Hydraulic connections

Two rotary swivel couplings at 1″ BSP handle trailer connections at 90-degree angles. Ball valves at 2″ BSP female isolate circuits during maintenance. The 2″ BSP to 50mm insert adapts tank connections to standard hydraulic fittings.

Reducing adapters step down from 1½” BSP to 1″ BSP male connections. T adapters at 1″ BSP split flow to different trailer circuits. A 1½” BSP female bush completes the fitting selection for various installation configurations.

Read this article next: DAF twin-line or tri-line wet kit?