Walk into any truck hydraulics workshop and you’ll hear the same story — twin-gear PTOs outlast single-gear units on heavy-duty applications.

The secret lies in load distribution. Two gears share the torque that would destroy a single gear, especially when running high-flow pumps or crane systems demanding constant power.

Why twin gears matter

Standard PTOs struggle when you’re running high-flow pumps or multiple hydraulic circuits. Single gears take all the stress, leading to premature wear and unexpected failures. Twin-gear designs distribute that load, handling 531 Nm torque ratings without breaking a sweat.

The real advantage shows during engagement. Twin gears engage smoother at low speeds — crucial for operators who need PTO power whilst crawling through construction sites or forestry operations. You can engage at 10-15 mph rather than coming to a complete stop.

Related products:

• Twin Gear Clutch PTO for ZF DAF MAN IVECO 12 AS Tronic Automatic

• Twin Gear PTO for ZF MAN DAF IVECO RENAULT 6S 36 – 6S 850

• Twin Gear PTO for ZF MAN DAF IVECO RENAULT 6S 850 6 S/AS 700 6S

• Twin Gear PTO for ZF MAN DAF IVECO RENAULT VOLVO 6/12 AS Tronic Inc

Technical specifications

Most twin-gear PTOs run 1:1.2 ratios, giving you slight overdrive for optimal pump speeds. The pneumatic control systems need 5-10 bar air pressure, integrating with existing truck air systems. Confirmation switches verify engagement before you start pumping.

Torque ratings vary by application. Light-duty units handle 260 Nm for standard tipping work. Heavy-duty models push 531 Nm — enough for demanding walking floor systems or high-pressure hydraulic cranes. Always match torque capacity to your intended use.

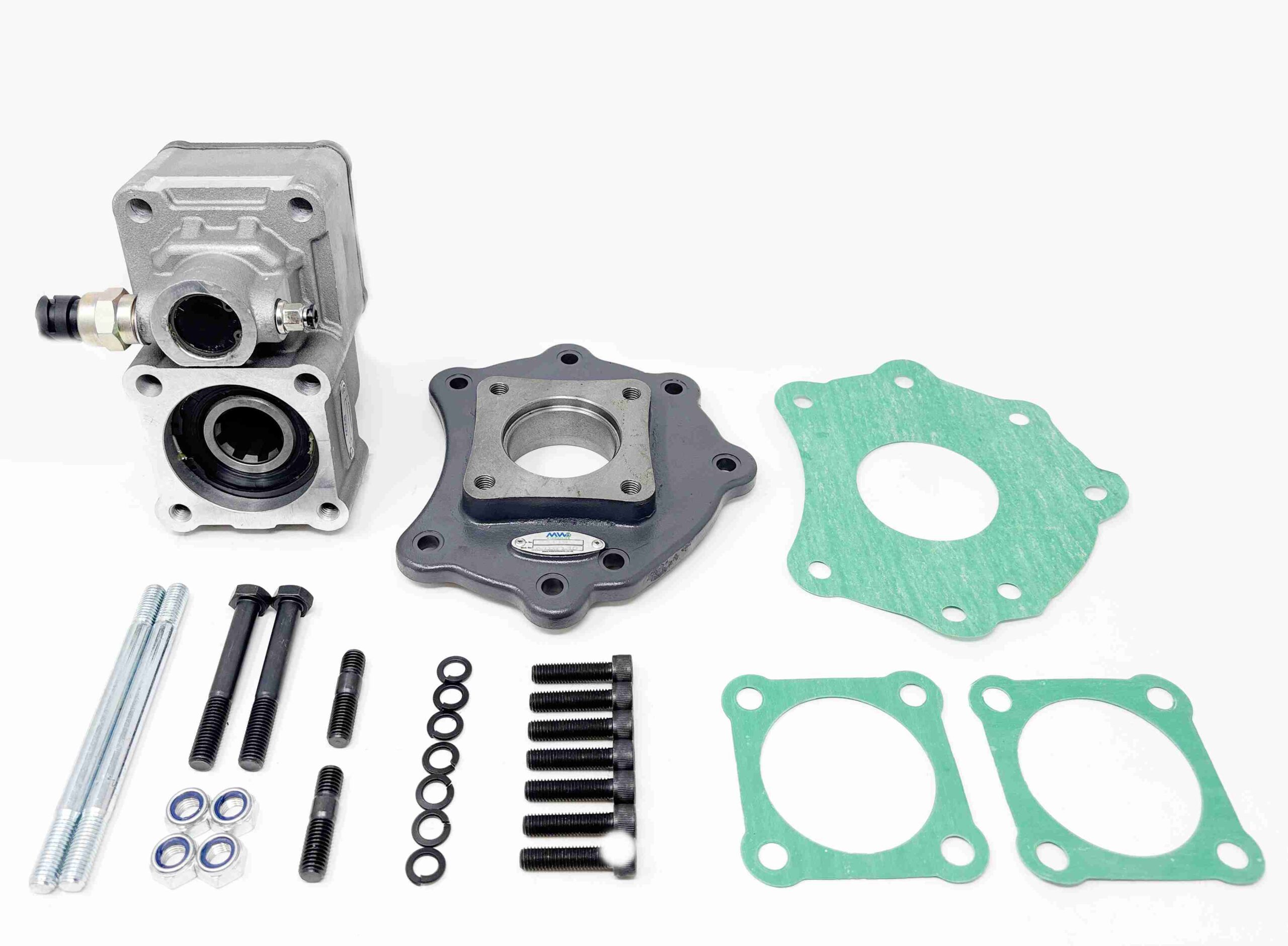

Installation requirements

Shaft length catches operators out more than anything else. ZF AS-Tronic boxes need different shafts depending on model year — 248mm for older units, 270mm for newer builds. Some 12AS1010 models require special-order 323mm shafts.

Gearbox compatibility extends across major manufacturers. ZF dominates the market, but Eaton units in older trucks work perfectly with correct adapter plates. Modern Traxon transmissions need specific PTOs designed for their electronic control systems.

Real-world applications

Tipper operators appreciate the smooth engagement when positioning under loading shovels. No more grinding gears or stalled engines — just flip the cab switch and go. Walking floor drivers benefit from consistent power delivery throughout long pumping cycles.

Recovery operators running heavy winches swear by twin-gear reliability. The distributed load means less downtime and fewer roadside failures. Construction firms operating crane trucks report 40% longer service intervals compared to single-gear units.

Maintenance considerations

Twin gears need proper lubrication from day one. Check gearbox oil levels religiously — low oil kills PTOs faster than overloading. Listen for unusual noises during engagement; grinding sounds indicate misalignment or worn teeth.

Annual inspections should include checking gear backlash and bearing play. Excessive movement means rebuild time. Most units give 5-7 years of hard service before major overhaul, though light-use applications stretch to a decade.

Your gearbox determines which PTO fits — not all boxes accept twin-gear designs. Check manufacturer specifications before ordering.

Modern automated transmissions often come PTO-ready, but older manual boxes might need modification or simply won’t accommodate twin-gear units at all.

Additional reading: DIY hydraulic wet kits – a guide to our products