Tri-line wet kits for MAN trucks – what to expect

—

MAN TGS, TGA, and TGX operators running both tipping and walking floor work need tri-line hydraulics that switch between circuits on demand.

Our kit fits Euro 3, 4, 5, and 6 models with ZF AS Tronic and ZF Traxon gearboxes, delivering 108 litres per 1000 RPM from a bent-axis pump controlled by manual diverter valves.

Products in this guide

Pump output

The bent-axis piston unit generates 108 litres for every 1000 engine revolutions, with pressure ratings spanning 350 bar in standard use, climbing to 400 bar at peak demand (additionally, bidirectional operation reverses oil direction for raising and lowering without altering pump rotation).

RPM limits sit at 1700 for sustained running, extending to 1900 when circuits need higher flow. Split flange inlets at 1″ BSP include seals and fixing screws. Discharge ports thread to 1″ BSP with hose tails fitted. Weight lands at 16kg.

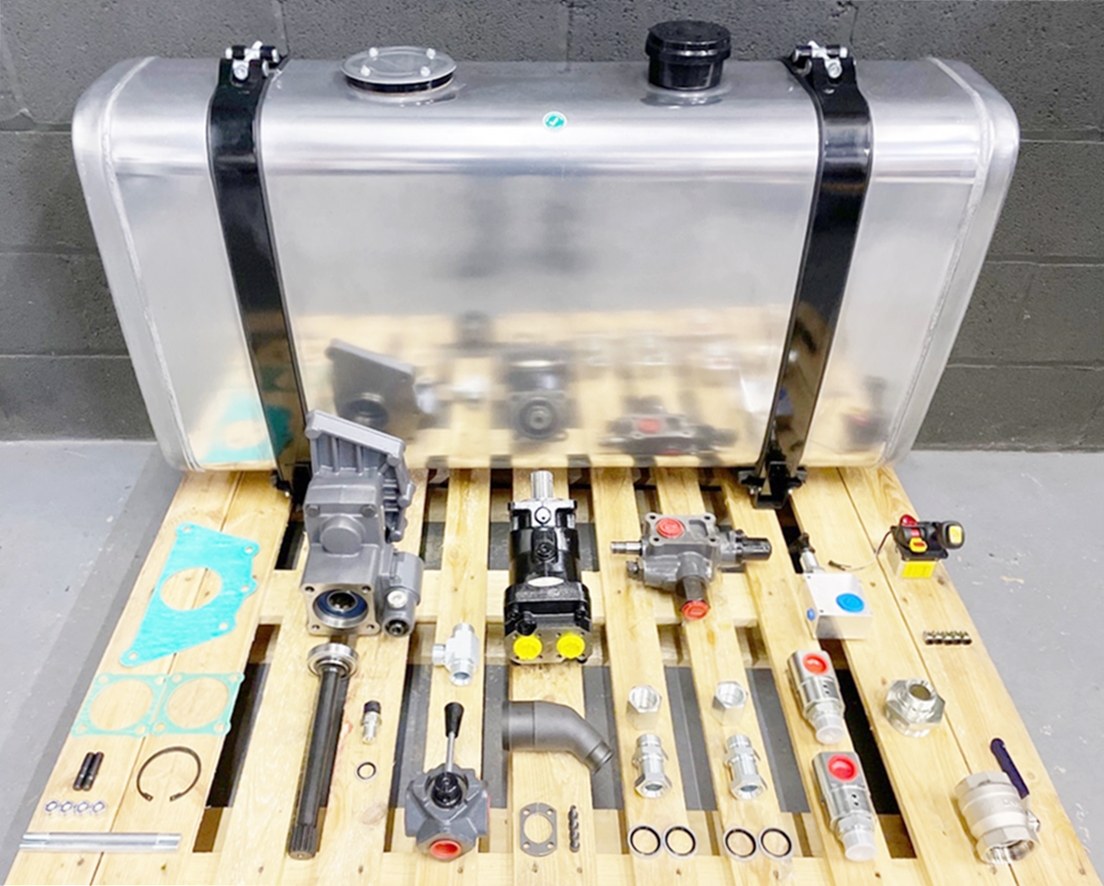

Tank specification

Aluminium construction mounts behind the cab, storing 190 litres in a body spanning 110cm width, 65cm height, and 32cm depth without fixtures counted.

Oil returns via two routes. The valve plate mounting surface takes one line at 1″ BSP female threads. A side-positioned adapter accepts the second at 1½” BSP male. Suction draws from the base adapter at 2″ BSP male threads.

Internal filters trap particles at a 25-micron size. Filler caps contain breather strainers with air elements installed. Level indicators show oil quantity without cap removal. Mounting straps, brackets, and rubber pads arrive in the kit.

Related: Comparing tipping wet kits: Volvo/Renault vs DAF/IVECO/MAN

Pressure control and flow distribution

Inline relief valves span 50 to 380 bar settings in stainless steel bodies locked by adjustment nuts. Maximum throughput reaches 100 litres per minute across test, inlet, outlet, and tank connections.

Three-way diverter valves route flow manually between circuits at open-centre design, handling 280 bar maximum via 1″ BSP female ports.

Tipping control valves move 140 litres per 1000 RPM at 180 bar working load, rated to 230 bar peaks. Connections for pump feed, tank return, and cylinder supply all thread to 1″ BSP female in a normally closed format.

Transmission fitment

The twin wheel clutch PTO bolts to the gearbox rear at a 1/1.2 ratio, rated for 531 Nm torque. Pneumatic actuation needs a 5 to 10 bar air supply. Quill shafts arrive where required, along with adapter plates, gaskets, and mounting hardware.

ZF AS Tronic boxes from 2005 to 2016 accept this PTO arrangement, while the 12 AS 2130 TD version takes 270mm shafts, and the 12 AS 2301, 2310, 2330 TD, and 2540 TD versions use 248mm shaft lengths.

Related: Tipping gear: powering your hydraulic operations

ZF Traxon transmissions from 2017/18 onwards take the same PTO. The 12TX family runs from 1410TD up to 3440TO variants. The 16TX series covers 1640TD models up to 3440TO units, each carrying different torque and ratio specifications.

Control system

The cab controller merges PTO activation with valve commands on 24-volt power. Ports at 1/8″ BSP size connect PTO circuits, air supply, exhaust routing, tipping commands, and lowering signals. Air pressure operates from 5 to 10 bar.

Fittings and adapters

Rotary swivel sets at 1″ BSP angle 90 degrees for trailer connections on walking floor circuits. Ball valves with 2″ BSP female threads shut off lines for maintenance.

A 2″ BSP to 50mm insert links tank outlets to main lines in male/male format. Reducing adapters step 1½” BSP down to 1″ BSP male/male threads. T adapters with 1″ BSP male threads split circuits in three directions.

Read this next: The difference between bent-axis and gear pumps for truck hydraulics