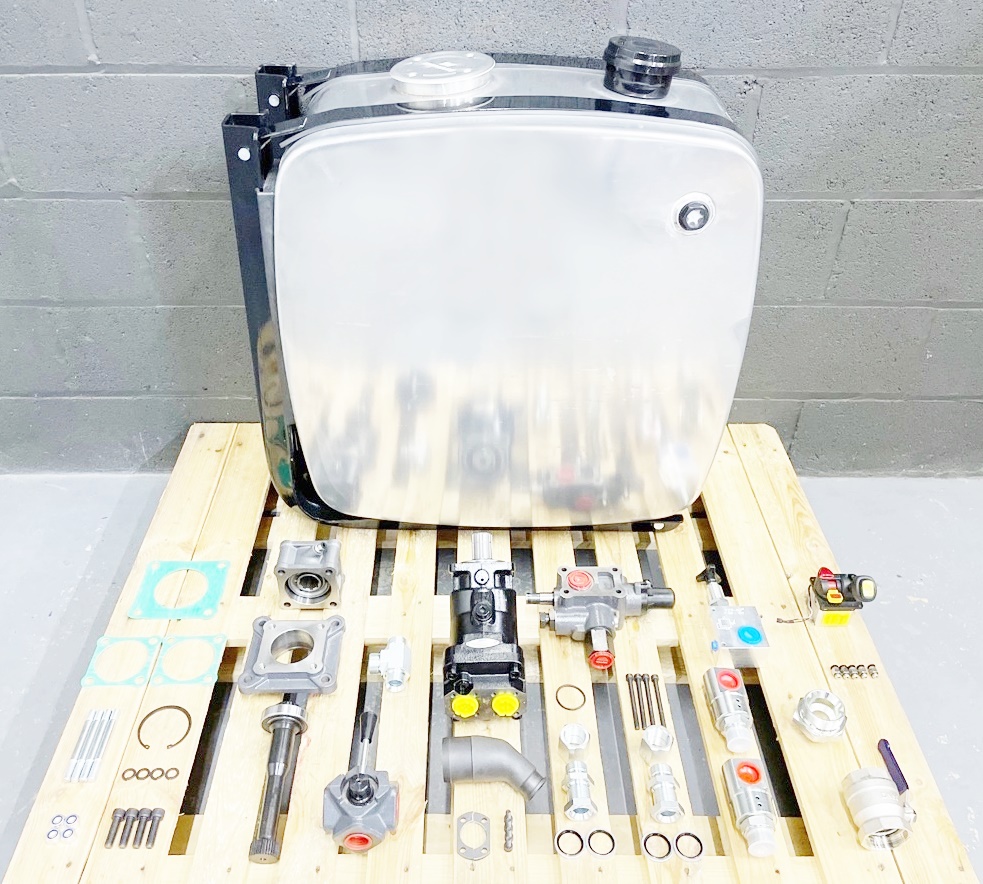

Renault tri-line wet kits for combination operations

—

Operators switching between tipping and walking floor work need hydraulic systems that manage three separate circuits.

Our tri-line kit covers Renault Premium DXI trucks from Euro 4 and 5, plus T Range models from Euro 6, using a bent-axis pump that feeds walking floor circuits and tipping functions through manual diverter switching.

Products in this guide:

Tank specification

Aluminium tanks holding 200 litres mount to the chassis side, measuring 38cm wide, 75cm tall, and 75cm deep without mounting fixtures included in these dimensions.

One return line connects at the directional valve mounting plate through 1″ BSP female threading, with the second feeding through an upper rear adapter at 1½” BSP male.

Pump suction takes oil from a bottom rear adapter threaded to a 2″ BSP male. Internal filters work at a 25-micron specification, and the filler cap incorporates breather strainers with air filter elements. Oil level indicators, brackets, straps, and rubber mounts form part of the tank assembly.

Related: Renault single-line wet kits for tipping operations

Pump output

The bent-axis piston pump displaces 108 litres per 1000 RPM with 350 bar working pressure and 400 bar maximum rating, running continuously at 1700 RPM with 1900 RPM maximum capability when flow demand increases.

The pump rotates bidirectionally, taking inlet feed through 1″ BSP split flange connections that include seals and screws. Outlets thread to 1″ BSP with hose tails included. Weight reaches 16kg.

Pressure and flow control

Inline relief valves offer variable adjustment from 50 to 380 bar in stainless steel construction with locking nuts. Maximum flow sits at 100 litres per minute through the test, inlet, outlet, and tank ports.

The three-way manual diverter valve operates at open-centre design through 1″ BSP female ports, handling 280 bar maximum pressure to direct flow between circuits.

Directional tipping valves displace 140 litres per 1000 RPM at 180 bar working pressure with 230 bar maximum capability, connecting pump, tank, and cylinders through 1″ BSP female ports using a normally closed configuration.

Transmission connection

The pneumatic PTO mounts to the gearbox rear at a 1:1 ratio with a 245 Nm torque rating, engaging through air pressure between 5 and 10 bar.

AT2412C, AT2412D, AT2512E, AT2612D, and AT2612E I-Shift transmissions all accept this PTO configuration. The kit includes quill shaft, adapter plate, gaskets, fixtures, and connectors.

Renault Premium DXI trucks from Euro 4 and 5 take these gearboxes, as do Premium T Range models from Euro 6.

Control system

The tipping cab controller incorporates PTO switching alongside directional valve operation through five 1/8″ BSP ports that handle PTO, air inlet, air exhaust, tipping, and lowering circuits on a 24-volt supply with air pressure between 5 and 10 bar.

Hydraulic fittings

Two rotary swivel coupling sets at 1″ BSP positioned at 90 degrees connect walking floor trailer lines, while one ball valve at 2″ BSP female/female isolates circuits during maintenance.

It includes one 2″ BSP to 50mm male/male insert, one reducing adapter from 1½” to 1″ BSP male/male, and one T adapter at 1″ BSP male/male/male.

Read this next: Comparing tipping wet kits: Volvo/Renault vs DAF/IVECO/MAN