A PTO connects to a truck’s transmission or transfer case, with the PTO output shaft connecting to the input shaft via gears or a belt. This can power a wet kit – as the engine spins the transmission, the PTO turns and drives the hydraulic pump, directing hydraulic fluid through valves to cylinders/motors to operate the equipment.

Specifying a PTO

All PTO devices have three important specifications:

- Torque rating: Expressed in lb-ft or Nm, this indicates the maximum torque the PTO can continuously transmit.

- Horsepower rating: Indicates the maximum horsepower the PTO can produce

- Duty cycle rating: Light duty, medium duty, heavy duty – indicates how many hours per day and type of usage the PTO is designed to withstand.

Decide on the PTO mounting location – standard options are transmission mounted, engine flywheel mounted, or chassis mounted. Choose the PTO drive type to suit – shaft-driven or gear-driven. Shaft-driven is more common for heavy-duty applications.

To match the hydraulic pump, specify the PTO rotation direction, speed ratio, and spline count. Truck transmissions and engines spin in different directions, so the PTO needs to match for compatibility’s sake.

Browse our PTOs by manufacturer to make life easy:

Installing a PTO

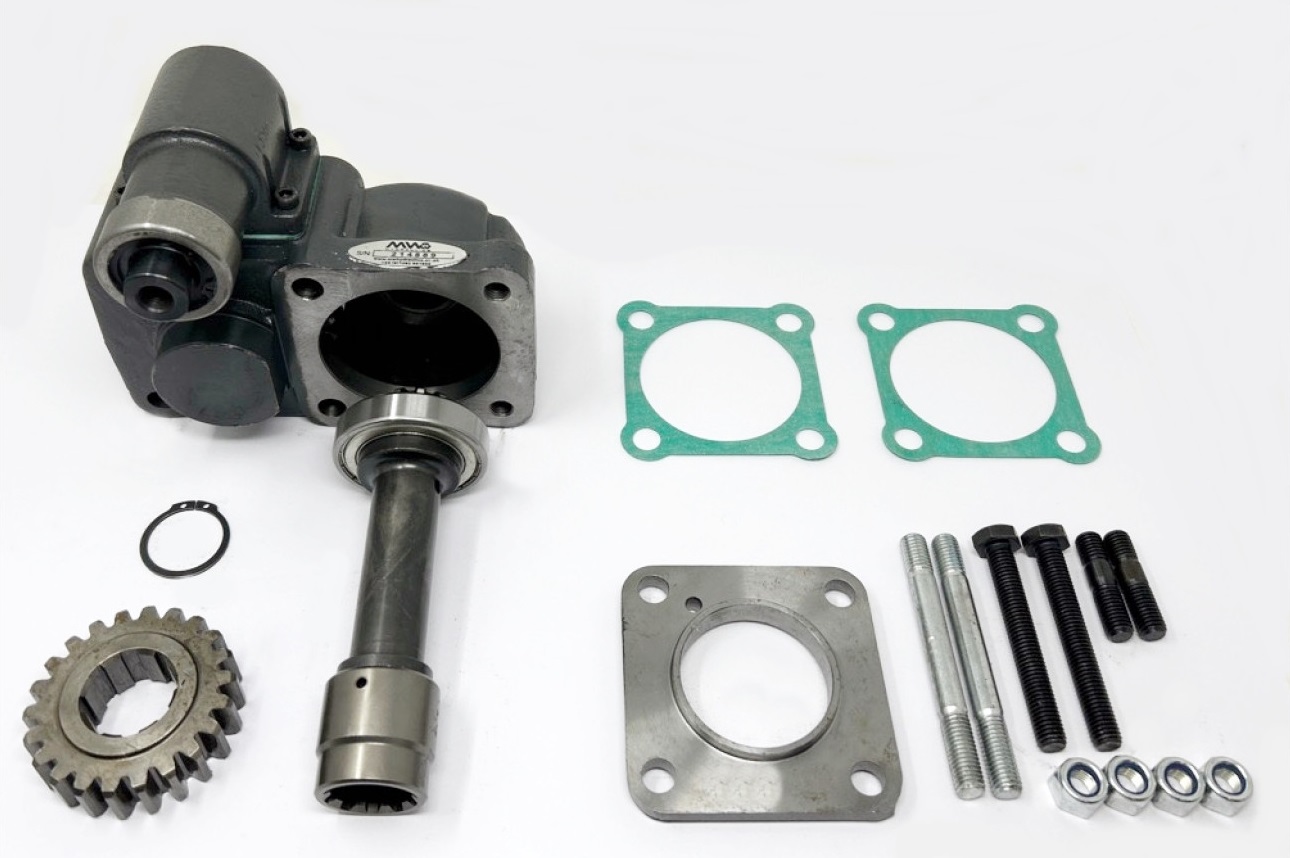

Installing a PTO and complementary hydraulic system on a commercial truck requires a “wet kit.” It’s essentially retrofitting the vehicle to transfer engine power to hydraulic components. It requires installing the PTO unit, hydraulic pump, reservoir, valves, cylinders, and hoses to integrate the system with the truck’s chassis.

With a wet kit, you can run equipment like a dumping bed or concrete mixer with the vehicle’s engine via the PTO and hydraulic power transmission.

We have guides covering single- and 2-line wet kits and 2-line and 3-line wet kits. The more lines there are, the more powerful and capable the wet kit; the PTO powers the wet kit and is a critical component for system reliability.

Maintaining a PTO

Power take-offs are generally very reliable drivetrain components. However, longevity is impacted by installation quality, proper operation, and maintenance procedures.

If the initial fit is shoddy – maybe the mounting is crooked, or the alignment is off – it can quickly wear down the internal parts and cut the unit’s life short. Proper bolt torque specs, precise measurements, using the right mounting hardware kit – doing it right from the start gives a PTO the best shot at going the distance.

Operation and maintenance is key too. If the operator uses the PTO nonstop for longer than the recommended duty cycle, it can overheat the components and strain the mechanical guts of the thing. Treating the equipment reasonably based on the manufacturer guidance helps maximise its lifespan.

Well-built PTOs that are correctly integrated on a truck, operated reasonably, and adequately maintained should deliver thousands of reliable hours of hydraulic accessory operation over years of use.

[…] Related: A quick guide to power take-offs (PTOs) […]