DIY hydraulic wet kits power your lorry’s auxiliary equipment. You’ll find our kits engineered for walking floor systems, ejector trailers, and combination setups.

Understanding wet kit configurations

Single-line systems route hydraulic fluid in one direction. Twin line configurations create continuous loops for demanding applications like walking floors.

Tri-line setups handle combination operations. You get tipping functionality alongside walking floor capability in one integrated system.

Related: An Expert Guide to Wet Kits

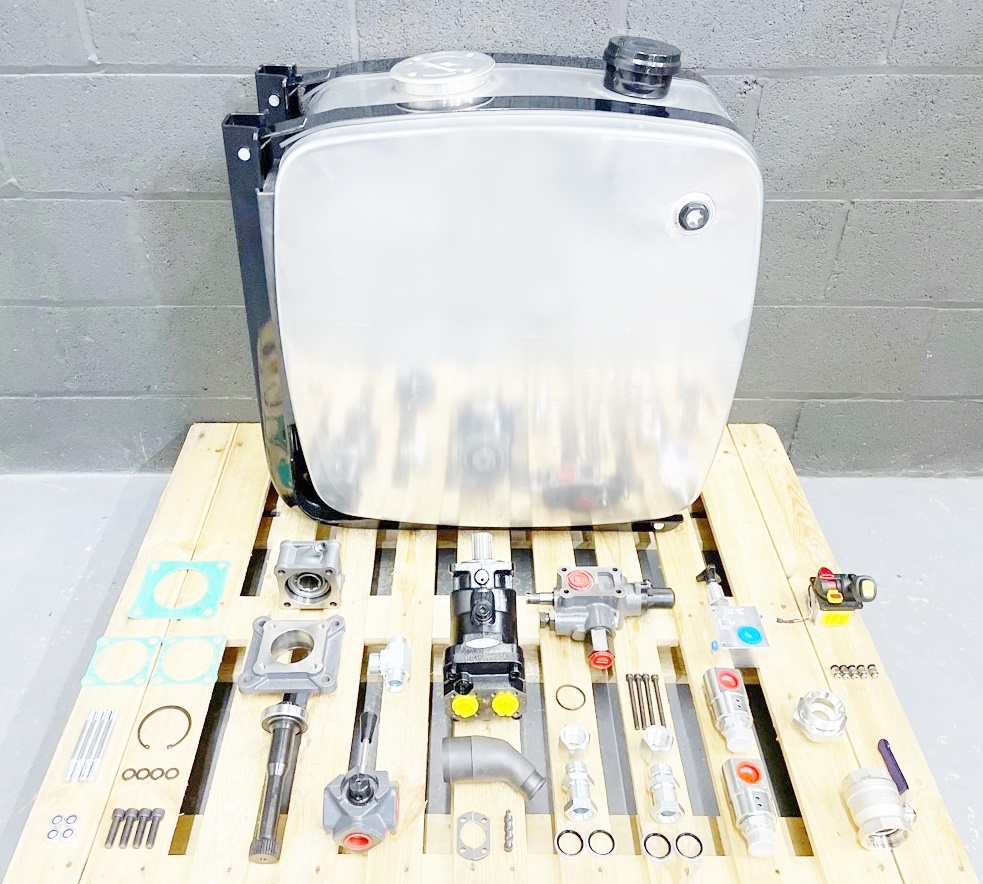

Key components in our kits

Every kit centres on a bent-axis piston pump. Our 108-litre displacement pumps deliver 350 BAR working pressure with 400 BAR maximum capacity.

Pumps operate at 1700 RPM continuously. You can push them to 1900 RPM for short bursts when extra power matters.

Oil tank specifications

Aluminium construction resists corrosion and reduces weight, with rear cabin-mounted tanks holding 190 litres, and side-mounted units storing 200 litres.

Each tank includes 25-micron internal filtration. Filler caps feature breather strainers with replaceable air filter elements for contamination control.

Pressure control systems

Variable inline relief valves regulate system pressure between 50-380 BAR. Test ports allow pressure verification without disconnecting lines. Maximum flow reaches 100 litres per minute for rapid cylinder movement.

Directional control valves

Manual diverter valves manage flow between different circuits. Open centre designs prevent pressure buildup when cylinders reach full extension.

Tipping valves feature normally closed construction. Air actuation provides a fail-safe operation if pneumatic pressure drops unexpectedly during use.

Power take-off assemblies

Clutch PTOs mount directly to your gearbox. Pneumatic control eliminates manual engagement, and confirmation switches verify proper clutch engagement before pump activation.

Standard ratios include 1:1 and 1:1.2 options. Torque capacity reaches 531 Nm for heavy-duty applications requiring maximum power transfer.

Control systems

Cab-mounted controllers integrate PTO activation with directional control. LED indicators confirm system status, and 24-volt operation matches standard lorry electrical systems.

Air pressure requirements range from 5-10 BAR. Controllers include dedicated ports for PTO engagement, tipping, and lowering functions.

Gearbox compatibility

Our kits fit ZF AS Tronic gearboxes from 2005-2016. Newer ZF Traxon models from 2017 onwards require specific adapter plates.

Shaft lengths vary between models. 248mm and 270mm configurations cover most applications. Check your gearbox specifications before ordering.

Installation considerations

Hydraulic hoses require custom lengths for each chassis configuration. We calculate exact measurements from your PTO location to valve mounting points.

Rotary swivel couplings eliminate torsional stress during articulation. Ball valves isolate damaged circuits without shutting down your entire hydraulic system.

Related: A Quick Guide to Retrofitting a Truck Wet Kit

Application-specific configurations

Walking floor kits require twin-line setups for continuous operation. Higher flow rates and specialised valve configurations handle repetitive cycling demands.

Tipping applications work with single-line systems. Lower cycle counts and simpler valve arrangements reduce complexity and maintenance requirements.

Combination kits merge both capabilities. Tri-line plumbing separates functions, and manual diverters let you switch between tipping and walking floor modes.

Choosing your configuration

Match pump displacement to your application’s flow requirements. Walking floors need higher flow rates than basic tipping operations.

Tank location affects weight distribution. Rear cabin mounting suits most applications, and side mounting provides better access for maintenance.

View our complete range: