Walking floor trailers need twin-line systems. Combination operations running both walking floors and tipping need tri-line setups. The difference comes down to how many functions you run simultaneously. Read on for a complete guide.

Products in this guide:

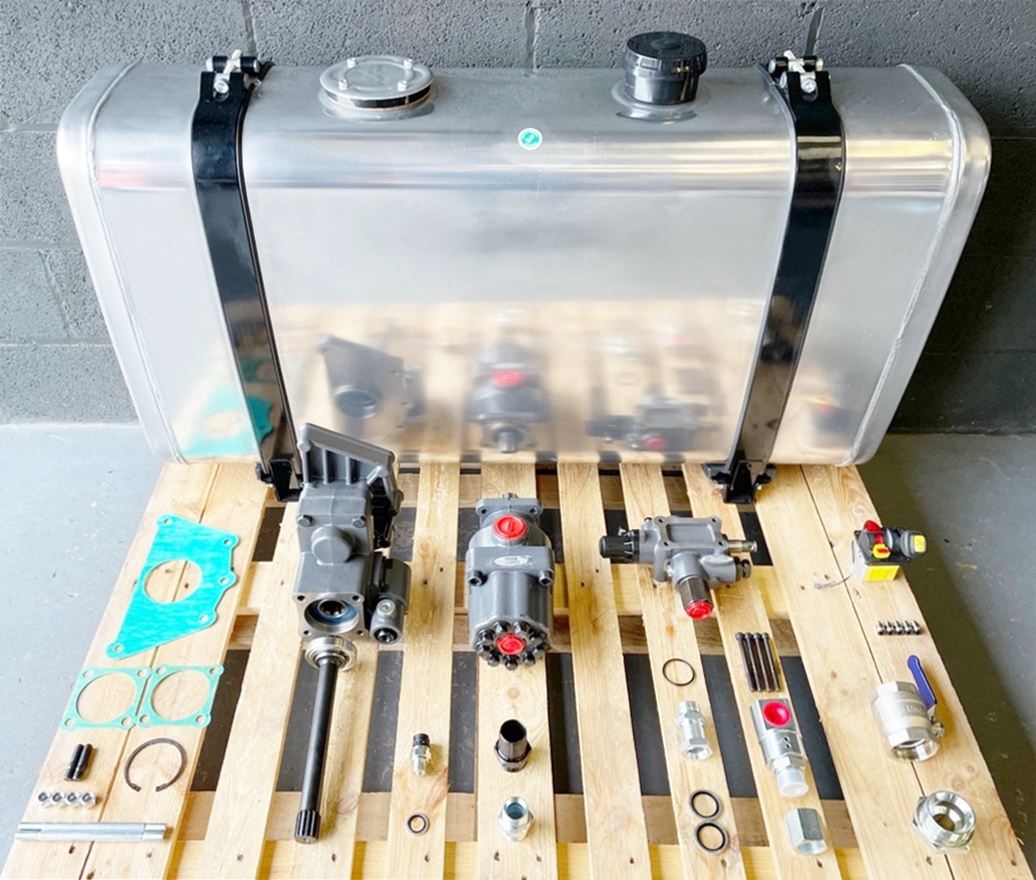

• Tri-line: Hydraulic Wet Kit Tipping & Walking Floor Combi DAF CF XF XG

• Twin-line: Hydraulic Wet Kit Walking Floor Twin Line DAF CF XF XG Euro 5 6

Twin-line systems

Twin-line kits handle two hydraulic circuits. Walking floors use one line for forward floor movement, another for reverse. You push material out or pull it back, depending on which circuit you engage.

DAF twin-line kits use 200-litre side-mounted tanks at 38cm wide by 75cm high. Side mounting keeps weight off the rear and maintains chassis clearance for trailer connections.

Inline pressure relief valves adjust from 50-380 bar. You dial pressure to match different materials. Sawdust needs less pressure than aggregates. Variable settings prevent floor damage and reduce power waste.

Twin-gear clutch PTOs run at 1:1.2 overdrive with 531Nm torque. The 1:1.2 ratio increases pump speed beyond engine RPM. Walking floors need this extra flow to maintain floor speed during material movement.

PTO air switches control engagement. Maximum pressure sits at 10 bar, minimum at 5 bar. Single-way operation suits walking floors where you engage and run continuously.

Tri-line systems

Tri-line kits add a third circuit for tipping operations. You run walking floors on two lines, tipping on the third. Haulers switching between grain tipping and aggregate walking floors need this flexibility.

DAF tri-line kits use 190-litre rear cabin-mounted tanks at 110cm wide by 65cm high. Rear mounting works when you need access to all three circuits from one position. Tank capacity drops 10 litres because rear mounting limits available space.

Related: Comparing tipping wet kits: Volvo/Renault vs DAF/IVECO/MAN

Tri-line kits add directional tipping valves rated at 140L/1000 RPM. Working pressure sits at 180 bar, maximum at 230 bar. These valves handle intermittent tipping operations separate from continuous walking floor work.

Manual diverter valves switch between circuits. Open-centre design at 1″ BSP handles 280 bar maximum. You select tipping or walking floor operation before engaging the PTO.

Tipping cab controllers integrate PTO switching with circuit selection. Maximum pressure runs to 10 bar, minimum at 5 bar. Separate ports for tipping and lowering give you directional control without multiple switches.

PTOs match twin-line specifications with twin-gear clutch design at 1:1.2 ratio and 531Nm torque. The same overdrive arrangement suits both walking floor and tipping operations.

Component differences

Twin-line kits include 1½” BSP bushes alongside reducing adapters from 1½” to 1″ BSP. Tri-line kits include reducing adapters but skip the bushes.

Both systems use two rotary swivel couplings at 1″ BSP. Ball valves at 2″ BSP isolate tank circuits during maintenance.

T adapters appear in both specifications at 1″ BSP. These split flow to trailer connections without additional fittings.

Making your selection

Choose twin-line for dedicated walking floor work where side-mounted tanks improve stability and component count stays minimal.

Choose tri-line when you switch between walking floors and tipping. Rear tanks give better circuit access. Manual diverters prevent cross-operation between functions.

Read this next: What to look for in walking floor hydraulics