A combination wet kit is a versatile hydraulic system that allows your truck to power multiple hydraulic functions.

Unlike single-line wet kits designed for specific lightweight tasks like tipping, combination kits can power heavier equipment, including walking floors, trailers, and tipping bodies, making them a fantastic modification for fleet vehicles.

PSI ratings

PSI (Pounds per Square Inch) represents how much force a combination wet kit can generate. Higher PSI means more power and capability to operate hydraulic equipment.

Operating within the correct PSI range is crucial for safety and performance. Too low pressure may cause equipment to function poorly or fail, while excessive pressure can lead to component damage or catastrophic failures.

Related: How to choose a walking floor wet kit

MW Truck Parts sells kits rather than individual parts for optimal performance. The PSI of the system influences the overall design of the wet kit, including fluid reservoirs, line sizes, and cooling requirements.

Critical components of a combination wet kit

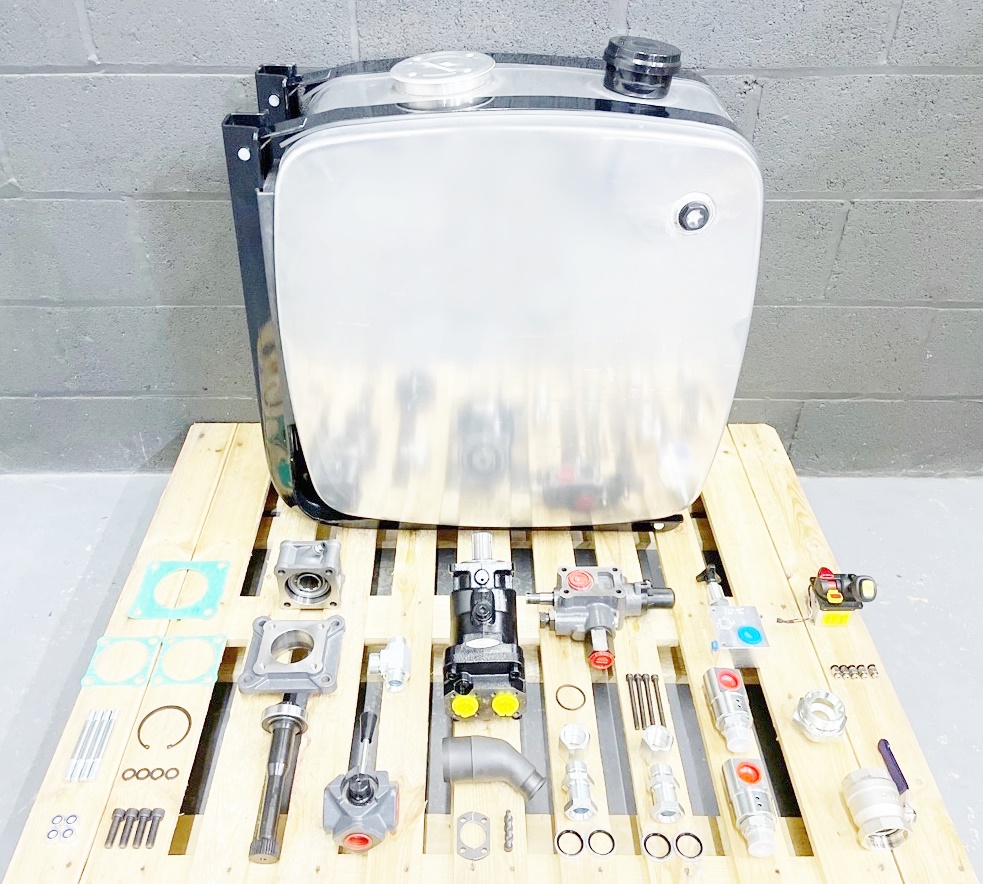

Your combination wet kit typically includes the following:

Hydraulic tank

A high-capacity aluminium tank (usually 200 litres or more) stores the hydraulic fluid with ports for return lines, pump feed, and accessories.

Hydraulic pump

A powerful bi-directional piston pump, often with 108 litres per 1000 RPM displacement, provides the necessary hydraulic pressure and flow.

Control valves

Multiple valves, including diverter and directional tipping valves, allow you to control and direct hydraulic flow to different functions.

Related: A guide to control valves for truck hydraulics

PTO (Power Take-Off)

The PTO connects to your truck’s transmission, driving the hydraulic pump with an adapter plate and pneumatic control for easy engagement.

Cab controller

An electronic controller in your cab lets you manage PTO engagement and control various hydraulic functions with a lever.

Installation considerations

Ensure compatibility with your truck’s make, model, and gearbox. For instance, a hydraulic wet kit combination for a Volvo FH FM Euro 4, 5, 6 won’t fit an IVECO truck.

Allow adequate space for the tank, typically side-mounted on the chassis, and don’t knock or damage it before installation.

Plan the routing of hydraulic lines to reach all intended equipment. The lines should ideally be protected so they can’t be easily cut.

Professional installation is best to ensure proper integration with your truck’s systems. We don’t recommend self-installation.

Maintenance tips

Your combination wet kit should power thousands of cycles, although premature wear can be expected with poor maintenance.

Regularly check hydraulic lines, fittings, and connections for any signs of leaks or damage, and promptly address leaks to prevent hydraulic fluid loss.

Fast leaks—for example, from cuts in the line—can be monitored using gauges, although most leaks are slow (hence the need for regular inspection).

Periodically test the operation of the PTO and hydraulic system to ensure smooth performance. Address any abnormal noises, vibrations, or malfunctions before powering up another equipment cycle.

Further reading: Understanding wet kit specs for hydraulic systems