Renault single-line wet kits for tipping operations

—

Renault Premium DXI and T Range trucks need dedicated tipping hydraulics that match I-Shift transmission mounting points.

We supply two configurations based on tank placement, with side-mounted systems using 200-litre tanks for better weight distribution, while rear cabin kits fit 190-litre tanks where chassis space limits side mounting options.

Products in this guide:

- Hydraulic Wet Kit Tipping Renault DXI T Range Volvo FH FM Euro 4 5 6

- Hydraulic Wet Kit Tipping Trailer Volvo FH FM Renault DXI T Range Euro 4 5 6

Side-mounted tank systems

The 200-litre aluminium tank bolts to the chassis rail at 38cm wide, 75cm tall, and 75cm deep without mounting fixtures, keeping payload balanced while leaving the rear frame clear for fifth wheel operation.

Return oil feeds through two separate lines, with the first connecting through the directional valve mounting plate at 1″ BSP female, while the second enters via the upper rear adapter at 1½” BSP male, and the pump feed draws from the bottom rear adapter.

Internal 25-micron filters trap contamination before oil reaches the pump, while breather strainers in the filler cap prevent dirt ingress during refilling, and oil level indicators show fluid status without removing the cap.

Related: A guide to our Mercedes walking floor wet kit (twin-line)

Rear cabin tank alternative

Rear-mounted tanks hold 190 litres in an aluminium body measuring 110cm wide, 65cm high, and 32cm deep before fixtures, with the broader and shallower profile fitting behind the cab where vertical clearance drops but horizontal space opens up.

Return routing changes slightly from side-mounted versions, feeding one line through the directional valve plate at 1″ BSP female and routing the second through a side-mounted upper adapter at 1½” BSP male.

Pump and valve specifications

Nine-piston units displace 85 litres per 1000 RPM at 250 bar working pressure with 350 bar maximum rating, using bidirectional rotation to handle raise and lower cycles without reversing pump drive direction at maximum speeds up to 1300 RPM.

Inlet ports thread at 1¼” BSP with 1″ BSP outlets fitted with hose tails. Directional tipping valves handle 140 litres per 1000 RPM at 180 bar working pressure with 230 bar peaks, using normally closed solenoids to prevent accidental body movement.

Related: Which applications suit tandem pumps?

PTO and controls

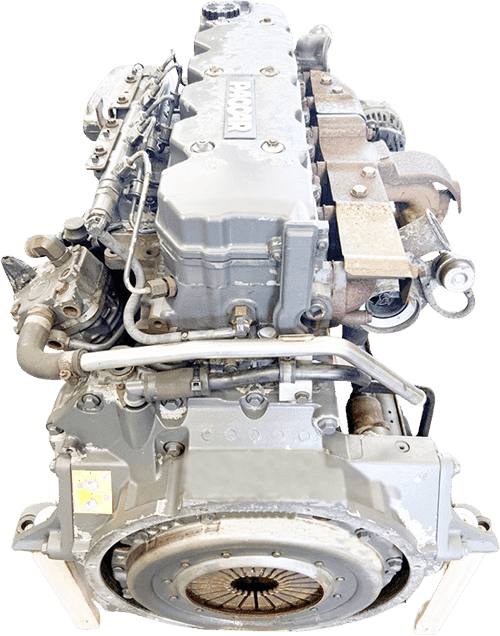

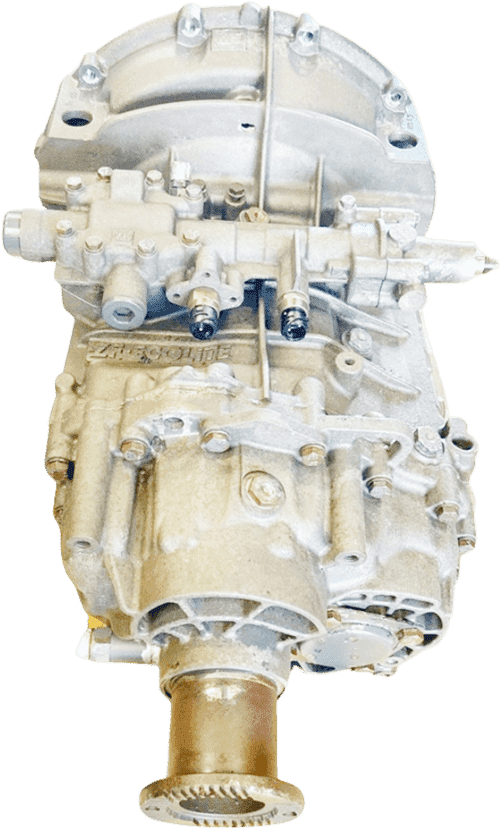

Pneumatically-controlled PTO blocks mount to the rear of AT and ATO I-Shift gearboxes at a 1:1 drive ratio with 245 Nm torque capacity, suited to tipping operations where engagement happens at idle rather than under load.

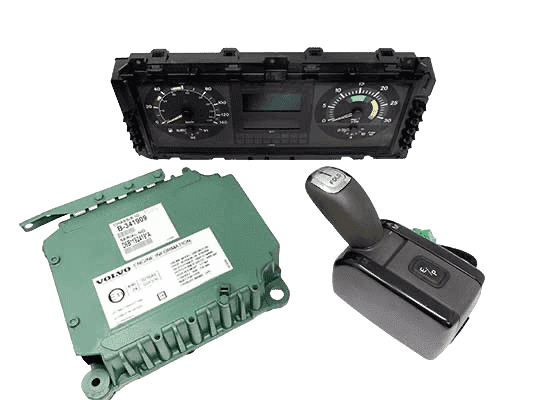

Tipping controllers combine PTO switching with directional valve operation through separate air circuits running between 5 and 10 bar on a 24-volt electrical supply, with separate tipping and lowering ports giving independent control over body direction.

Gearbox coverage

AT and ATO I-Shift transmissions from C, D, and E series all accept this PTO arrangement, covering AT2412C through ATO3112C in the C series, AT2412D through ATO3512D in the D series, and AT2412E through ATO3512E in the E series.

Renault Premium DXI trucks from Euro 4 and 5 use these gearboxes across different engine outputs, while Premium T Range models from Euro 6 share the same I-Shift mounting points.

Hydraulic fittings

Single rotary swivel couplings at 1″ BSP connect trailer cylinders at 90-degree angles, while ball valves at 2″ BSP female shut off circuits during maintenance, and a 2″ BSP to 38mm insert bridges tank outlets to standard hydraulic connections.

Order hoses separately based on your trailer’s cylinder ports and required lengths.

Read this next: Comparing tipping wet kits: Volvo/Renault vs DAF/IVECO/MAN