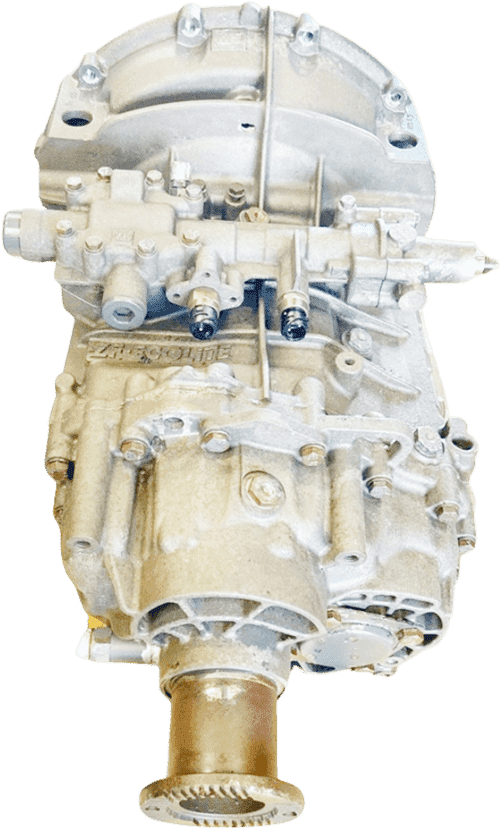

A twin flow axis pump delivers two separate hydraulic outlets from a single pump, creating independent flow circuits for complex truck operations.

This bent-axis design generates dual hydraulic streams with different displacement ratings, powering multiple functions simultaneously without pressure interference.

Dual outlet configuration

Twin flow pumps feature two distinct outlet ports, each with separate displacement ratings. Port A typically handles primary functions with higher flow requirements, while Port B manages auxiliary equipment with smaller displacement needs.

Outlet configurations range from matched 53L/53L arrangements to split 56L/26L combinations. Each outlet maintains independent pressure capability up to 400 BAR maximum rating.

Related: How to specify the correct bent-axis pump

Mounting and connection specifications

Standard 4-bolt ISO mounting flanges accommodate European truck manufacturers. The 8-spline input shaft connects directly to PTO systems without requiring additional coupling hardware.

Outlet connections use 3/4″ BSP threading for both ports. The 50mm flange diameter provides secure mounting whilst maintaining compact dimensions for space-limited installations.

Speed and displacement characteristics

Maximum shaft speeds reach 1850 RPM across displacement variants. Higher displacement combinations may require reduced operating speeds to maintain component longevity under continuous operation.

Fixed displacement design ensures consistent flow output regardless of pressure variations. This eliminates the complexity of variable displacement systems whilst providing predictable performance characteristics.

Application benefits

Forestry equipment benefits from independent control of boom and attachment functions. Construction machinery operates primary lifting circuits separately from auxiliary systems like stabilisers and tool attachments.

Related: How to specify the correct piston pump

Mining dump trucks use split flow for body lifting and tailgate operation. Material handling equipment manages crane functions independently from truck-mounted accessories.

Recycling vehicles operate vacuum systems on one circuit whilst powering compaction or lifting equipment on the secondary flow path.

Installation considerations

Single inlet design simplifies hydraulic system plumbing compared to dual pump installations. Weight considerations include 18 KG total mass requiring adequate mounting support for operational forces.

Right-hand rotation (clockwise) matches standard PTO configurations across European truck manufacturers. The compact design reduces installation complexity compared to separate pump mounting arrangements.

Efficiency advantages

Combined operation from a single input reduces parasitic losses compared to multiple pump systems. Lower noise levels result from precision manufacturing and balanced internal components.

Extended service life comes from reduced mechanical complexity and fewer wearing components. Compact dimensions allow installation in restricted spaces where dual pump systems cannot fit.

System pressure capabilities

Working pressure ratings handle demanding applications requiring a sustained high-pressure operation. Maximum 400 BAR capability provides safety margins during load spikes without requiring oversized downstream components.

Pressure independence between outlets prevents cross-contamination of circuit pressures during the simultaneous operation of primary and auxiliary functions.

Additional reading: The difference between bent-axis and gear pumps

[…] Additional reading: What is a twin flow-axis pump? […]

Hello

A twin flow is a pump with a single feed in that has two output flows for operation two different hydraulically controlled components.