Gear pumps convert mechanical energy into hydraulic power for truck operations, including tipping, walking floors and crane systems.

Flow rates directly correspond to displacement values measured in litres per 1000 RPM, determining performance capacity across working conditions.

Flow rate selection factors

27l pumps provide sufficient flow for light distribution tipping operations with quick cycle times. Compact units weigh 10.5 kg and have 3/4″ BSP ports, making them compatible with space-limited installations while delivering optimal pressure during short-duration cycles.

34l variants balance flow capacity against power consumption for urban applications. These pumps maintain 230 BAR working pressure with minimal heat generation, ideal for frequent stops where cycle efficiency matters more than maximum flow volume.

Working with DAF LF or Renault Midlum distribution vehicles often warrants 27l or 34l models. Connection variations between 3-bolt UNI and 4-bolt ISO mount patterns accommodate different PTO specifications across European truck manufacturers.

Medium-duty applications

43l pumps serve construction and general haulage requirements with increased flow capacity. Weighing 12 kg with 1″ BSP ports, these units work effectively with twin-wheel PTOs found on CF and XF trucks using ZF transmissions.

Related: Powering truck hydraulics: A guide to hydraulic oil pumps

43l models benefit vehicles running regular cycles without extreme demands. Output pressure ratings of 220 BAR with 240 BAR peak capability match standard wet kit specifications for frequent operation without component stress.

51l units suit applications requiring greater oil volume without moving to piston pump designs. Maintaining a sensible weight of 10.5 kg allows fitting without chassis strengthening while providing flow rates matching medium construction specifications.

Heavy-duty requirements

90l pumps offer maximum flow rates for intensive operations, including walking floors and bulk handling. Larger 1-1/4″ BSP ports reduce flow restriction while maintaining pressure during extended running periods common in waste transport.

Heavy-duty variants feature reinforced casings and bearings for resistance against thermal stress. Bidirectional rotation capability works with both clockwise and counter-clockwise PTO designs without requiring specific pump variants for different gearbox types.

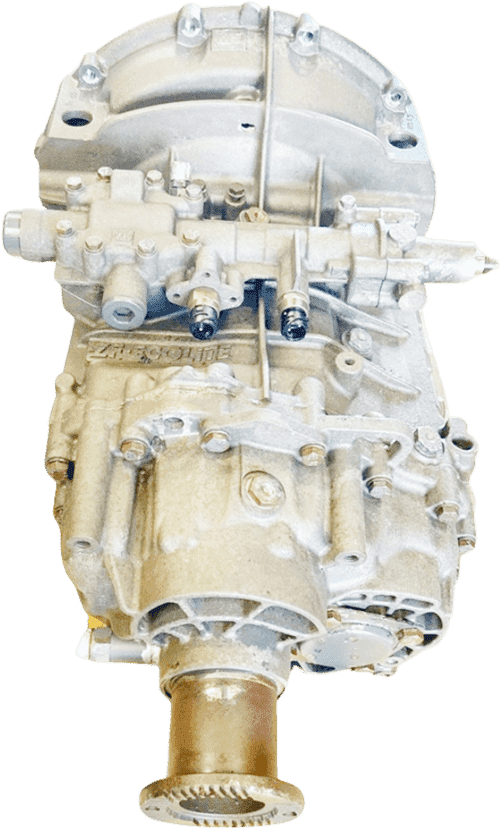

Mounting compatibility

ISO 4-bolt patterns provide standardised mounting for Mercedes, DAF, Volvo and Scania applications. Connection uniformity ensures straightforward replacement regardless of chassis configuration while maintaining direct drive alignment without adaptor plates.

Related: How do tandem gear oil pumps work?

UNI 3-bolt systems work primarily with Renault and Iveco transmissions through dedicated PTO variants. These mounting arrangements suit specific continental European transmission designs with distinct connection patterns separate from ISO standards.

Mount selection must match the pump displacement to the PTO torque output capabilities. Exceeding recommended limits risks transmission damage through excessive load during pressure spikes when operating with flow restrictors or relief valves.

Technical specifications

Operating pressure ratings between 220 and 230 BAR suit most hydraulic system requirements without special components. Maximum pressure limits reaching 240-250 BAR provide safety margins during load spikes without requiring specialised hoses or fittings.

Bi-directional rotation works with various PTO types without modification. Design features allow operation in either direction without efficiency loss, simplifying specification when working across mixed vehicle fleets with different transmission configurations.

Port sizes increase proportionally with pump displacement, starting at 3/4″ BSP for smaller units and reaching 1-1/4″ BSP for 90l models. Correct sizing prevents flow restriction during peak demand while maintaining appropriate connection strength.

Call 01262 601600 for compatibility advice across manufacturer ranges, including DAF, Scania, Volvo, Renault and Mercedes applications.

Additional reading: How hydraulic oil piston pumps work

[…] A guide to gear pumps […]

[…] A guide to gear pumps […]