PTOs connect gearboxes to hydraulic pumps for tippers, walking floors and cranes on Volvo trucks. Matching PTOs to gearbox types prevents equipment failure while maximising performance across different working conditions.

Gearbox types and compatibility

Volvo PTOs match gearbox models, not truck series. R/SR transmissions in F10, F12 and F16 trucks need rear-mounted units with pneumatic controls. Check transmission plates on casings for mounting details and model information.

VT series boxes in FL7 and FM7 trucks use different PTO designs than newer models. Mounting patterns stay consistent across years, letting you standardise hydraulic system designs regardless of fleet mix.

I-Shift AT/ATO transmissions need electronic integration for operation. Euro 6 vehicles use management systems with solenoid valves connecting via confirmation switches for engagement status.

Related: A guide to Scania PTOs

Torque ratings and configurations

Standard 1:1 ratio PTOs produce 245 Nm for tipping operations in distribution work. This is sufficient power for most city-based trucks, where hydraulic needs stay low throughout working cycles.

Twin-wheel 1:1.2 ratio units deliver 260 Nm by spreading forces across more contact points. Load distribution reduces wear during longer operational periods, which is common in construction applications.

Clutch-controlled versions reach 531 Nm for walking floors and heavy-duty tipping. Gear mechanisms engage while moving at speeds up to 15 mph, saving time for vehicles stopping frequently during routes.

Related: A guide to Renault PTOs

I-Shift selection factors

The AT2412C, AT2512C, and AT2812C boxes work with pneumatic systems connected to truck air supplies. Mounting points accept rear-positioned units without requiring drive shaft modifications for installation.

Switches feed information back through truck systems for safety monitoring. Ports on modern units connect directly to wiring looms without modifications, reducing workshop installation time.

Related: A Guide to Iveco PTOs

Pump options and mounting

Mounting patterns accept both 3-bolt UNI and 4-bolt ISO pump configurations. Connection standardisation works across model years regardless of transmission, simplifying replacement parts management.

27L and 34L gear pumps suit normal tipping cycles with standard PTOs. Using 43L pumps with twin-wheel units creates systems for intensive work patterns requiring higher flow rates throughout the operation.

Bent-axis piston pumps connected to clutch-type PTOs handle demanding walking floor trailers. Unlike standard gear pumps, these maintain temperature control during extended running periods.

Fitting and controls

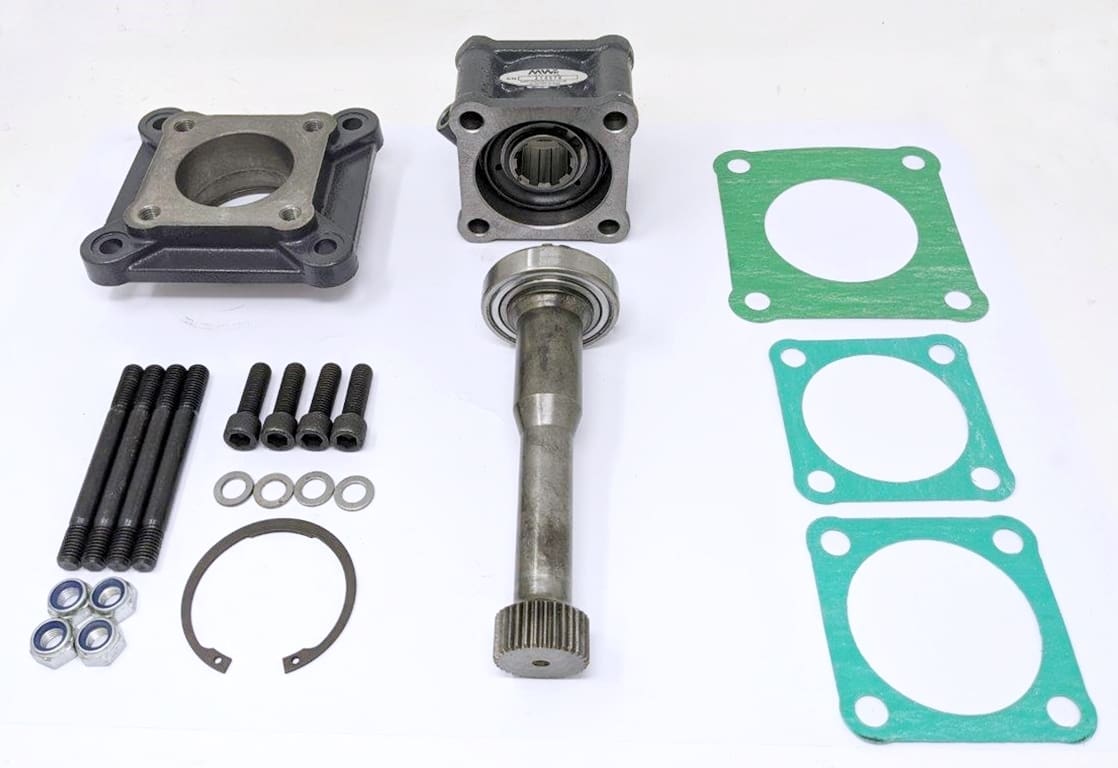

Kits come with gaskets and fixtures for leak-free installation. Torque settings matter during fitting to stop damage to transmission casings, requiring workshop attention to manufacturer specifications.

Vehicle air connects to control mechanisms through 1/4″ BSP fittings. Cab switches work through 2-way valves for simple operations or 3-way systems for complex hydraulic circuits requiring phased engagement.

Call 01262 601600 for quotes on complete systems, including tanks, pumps and controls. Stock extends beyond website listings with options for bespoke configurations to match vehicle requirements.

Further reading: A guide to Mercedes PTOs

[…] A guide to Volvo PTOs […]