If you’re running walking floor trailers alongside tippers, you know the headache of incompatible hydraulic systems. Tri-line wet kits solve this by giving you three hydraulic lines instead of two — letting one truck handle both trailer types without constant modifications.

How tri-line systems work

Standard twin-line wet kits pump oil through two lines — one supplies pressure, one returns to the tank. Perfect for tippers and walking floors, but not so suitable for running multiple hydraulic systems simultaneously.

Tri-line systems add a third dedicated return line, creating separate circuits for different functions. Your tipper still uses two lines as usual. Walking floor trailers tap into all three, using the extra return line to maintain precise flow rates.

One diverter valve switches between modes — flip it for tippers, flip it back for walking floors. No replumbing, no downtime.

Related: Tipping gear: powering your hydraulic operations

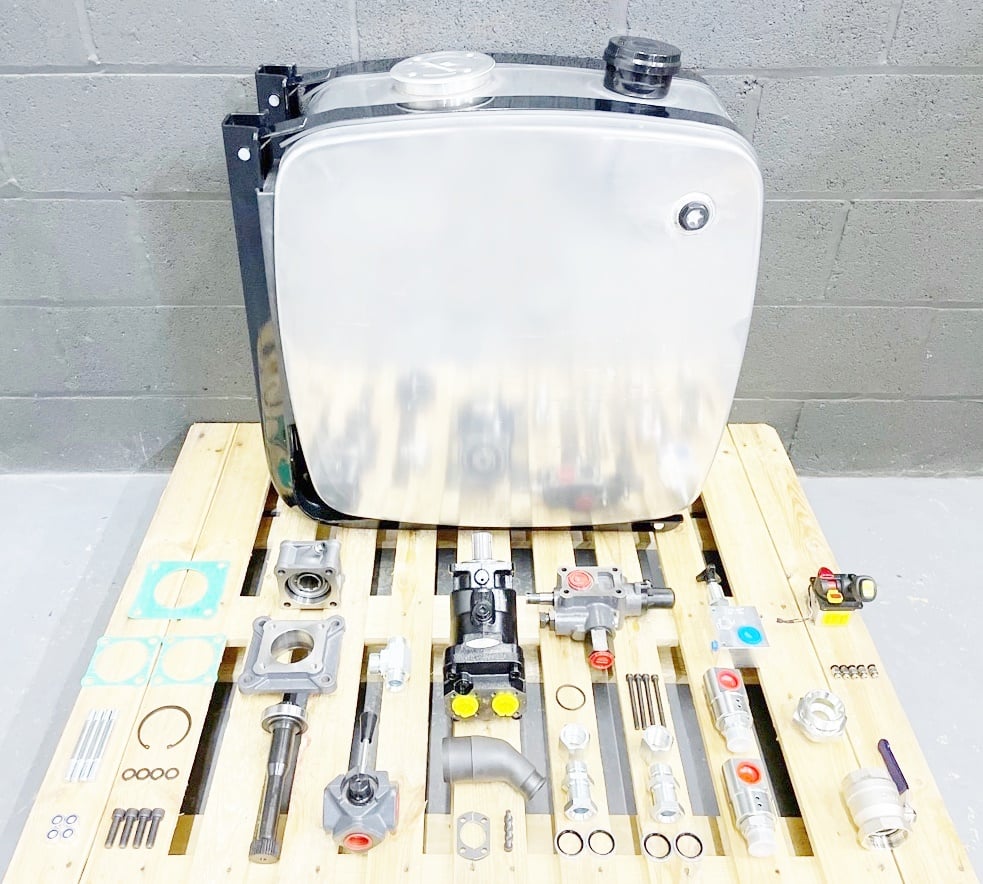

Essential components

The heart of any tri-line kit remains the bent-axis pump — typically 108L displacement for adequate flow rates. These bi-directional pumps handle the demands of both applications without breaking a sweat.

Your 190-litre aluminium tank needs three separate connections: pump feed at the bottom (2″ BSP), plus two return ports (1″ and 1½” BSP). Internal 25-micron filtration keeps contamination out of expensive components.

The manual diverter valve makes the magic happen. Open-centre design ensures oil flows freely when switching between functions. Inline pressure relief valves (adjustable 50-380 bar) protect against overloads.

Don’t forget the directional tipping valve — normally closed, air-operated, rated for 180 bar working pressure. Cab controllers with integrated PTO switches give drivers complete control without leaving their seat.

Installation considerations

Mounting varies by truck model. DAF units typically use rear-cabin tank mounting, whilst Renault prefers side-mounted configurations. Check your chassis rails and air tank positions before ordering.

PTO compatibility matters. ZF AS-Tronic and Traxon gearboxes need adapter plates and quill shafts. Older 12AS units use 248mm shafts, newer 16TX models run 270mm. Get this wrong and you’re looking at expensive machining work.

Hose routing requires planning. Three lines plus air controls mean more clutter than twin-line setups. Use proper P-clips and avoid heat sources — exhaust pipes kill hydraulic hoses faster than anything.

Related: DIY hydraulic wet kits – a guide to our products

Why operators choose tri-line

Flexibility drives the decision. One truck handles multiple trailer types, reducing fleet size and improving utilisation. Drivers appreciate simplified operations — no manual valve changes or auxiliary equipment needed.

Maintenance costs drop when you standardise on one system. Spare parts inventory shrinks, technicians learn one setup thoroughly, and troubleshooting becomes routine rather than detective work.

The investment typically pays back within months via improved truck utilisation. Add reduced maintenance costs and eliminated trailer swapping time, and the maths becomes compelling.

Whether you’re hauling aggregate in tippers today and wood chips in walking floors tomorrow, tri-line wet kits keep your trucks earning instead of sitting idle.

British operators have proven these systems in everything from Scottish forestry to Thames construction projects — harsh environments that demand reliable hydraulics.

Further reading: What to look for in walking floor hydraulics