An Expert Guide to Wet Kits

Are you looking to add hydraulic accessories to your commercial truck or fleet? A wet kit is the key to powering everything from dump beds and cranes to compressors and walking floors. In this expert guide, we'll walk you through the essentials of wet kits so you can make an informed decision for your specific needs.

What is a Wet Kit?

A wet kit is a self-contained hydraulic system that allows you to operate truck-mounted accessories using your vehicle's engine power.

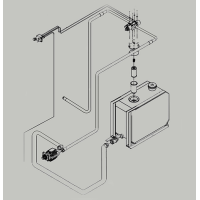

It consists of a hydraulic pump, reservoir tank, valves, hoses, and other components that work together to pressurise and direct fluid to the equipment you need to run.

The "wet" part refers to the hydraulic fluid that flows through the system – the fluid is the lifeblood that transmits power from the pump to the cylinders and motors of your accessories.

Types of Wet Kits

Single-line kits

The most basic type, using one hydraulic line for both pressure and return. Best for simple, occasional use accessories like dump beds.

2-line kits

Employ separate pressure and return lines. Great for powering individual tools like a crane or compressor. More control than single line.

3-line kits

Add a third return line to a 2-line system. Allows simultaneous operation of multiple high-flow accessories. Maximum power and flexibility.

Tipping Wet Kits

Ideal for dump trucks and trailers, tipping wet kits are engineered to provide the high fluid flow and pressure needed to quickly raise and lower heavy loads. They typically feature larger pumps and reinforced cylinders to handle the demands of frequent tipping cycles. The control valves are also designed for smooth, precise bed movement.

Walking Floor Wet Kits

Walking floor wet kits are made to power hydraulic walking floor trailers, which use a series of sliding slats to automatically load and unload cargo. The wet kit operates the hydraulic drive system that sequentially moves the floor slats. High pressure and flow are key to delivering the force needed to handle heavy loads. Precision valving ensures the floor walks smoothly and reliably.

Combination Wet Kits

For trucks that run multiple types of accessories, combination wet kits offer the ultimate in versatility. These systems have the valving and flow control to operate a mix of equipment, such as a dump bed, crane, and compressor, either independently or simultaneously. They're commonly built around a 3-line design to provide the necessary pressure, return, and tank lines for running diverse tools.

Choosing the Right Wet Kit

To select the optimal wet kit for your needs, consider these factors:

- Accessories: What equipment do you need to run, and how many tools at once? Basic needs suit a single or 2-line, while multiple heavy tools require a 3-line.

- Duty cycle: How often will you be running hydraulics, and for how long? Infrequent, lighter use is fine with simpler kits. Intensive daily operation demands a heavy-duty 3-line system.

- Pump and reservoir capacity: The pump's displacement determines hydraulic flow, while the tank's size dictates fluid capacity. Match these specs to your expected usage to prevent overheating and ensure steady performance.

Wet Kit Components

Hydraulic Tank

The reservoir that stores the hydraulic fluid. Tanks come in various capacities and can be side-mounted, rear-mounted, or chassis-mounted. Look for features like sight gauges, breather caps, suction filters, and internal baffles.

Hydraulic Pump

The heart of the wet kit is the pump, which pressurises and moves the fluid. Pumps are rated by displacement (flow) and maximum pressure. They can be gear, piston, or vane types and can be connected to the PTO for power.

Power Take-Off (PTO)

PTOs transmit rotational power from the truck's drivetrain to the hydraulic pump. They mount to the transmission or transfer case and engage/disengage with a lever or switch.

Control Valves

Direct the flow of pressurized fluid to operate the accessories. Valves come in manual, electric, or air-operated types. They control the speed, direction, and force of the hydraulic functions.

Hoses and Fittings

The plumbing carries fluid between components. Hoses are rated by diameter, pressure capacity, and temperature resistance. Fittings connect hoses to ports and include adapters, couplings, and swivels.

Filters

Remove contaminants from the hydraulic fluid. Filters can be located in the tank, on the return line, or in the pressure line. They are rated by micron size for particle capture.

Fluid Level/Temperature Gauges

Allow monitoring of the hydraulic reservoir's fluid level and temperature. It helps prevent low fluid conditions and overheating.

Control Cables/Switches

These engage and disengage the PTO and control accessories from inside the cab. They can be manual, electric, or pneumatic.

Installing a Wet Kit

Proper wet kit installation is crucial for reliable and safe operation. Key considerations include:

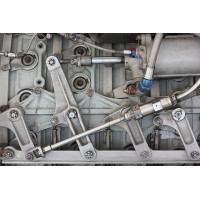

- Mounting and spacing components securely on the truck chassis.

- Ensuring hoses are sized correctly and routed away from heat and abrasion.

- Setting up the control valves and levers for easy operator access.

- Filling the reservoir with the appropriate hydraulic fluid.

- Testing the system thoroughly before putting it into service.

While handy truck owners can install basic kits themselves, it's often best to have a professional shop handle the job, especially for complex 3-line systems, ensuring everything is connected correctly and ready for trouble-free operation.

Maintaining Your Wet Kit

With proper care, a quality wet kit will deliver reliable service for many years. Follow these maintenance tips to keep things running smoothly:

- Check fluid levels regularly and top up as needed with the correct hydraulic oil.

- Inspect hoses and fittings for leaks, wear, or damage, and replace if required.

- Clean the tank breather cap and replace the return filter at recommended intervals.

- Ensure the pump is properly lubricated and mounting hardware is secure.

- Operate all functions periodically to prevent sticking and keep seals conditioned.

- Don’t exceed the wet kit’s maximum load rating – for example, loading equipment that is heavier than the wet kit can support.

Related Articles

What is a pre-assembled hydraulic wet kit?

Pre-assembled hydraulic wet kits contain all the components necessary for the desired application—whether tipping, walking floor, or a combination kit for various equipment—for your specific vehicle brand, such as Volvo or MAN...

Understanding wet kit specs for hydraulic systems

A wet kit uses hydraulic fluid to power various functions on a vehicle, such as tippers, walking floors, and tankers. The "wet" designation comes from the fluid that flows through the system. Wet kits have several key components that work together to perform hydraulic operations efficiently and safely...

Related Products

Hydraulic Wet Kit Combination for Volvo FH FM Euro 4, 5, 6 (With PTO Switch)

Hydraulic Wet Kit Combination for Volvo FH FM Euro 4, 5, 6 (With PTO Switch) We s..

£2,700.00 Ex Tax: £2,250.00

Hydraulic Wet Kit Walking Floor for IVECO STRALIS, S WAY Euro 4, 5, 6 (With PTO Switch)

We supply single and twin line hydraulic walking floor system wet kits for most makes and models suc..

£2,880.00 Ex Tax: £2,400.00

Tags Wet Kits

Up to 85% off RRP

Up to 85% off RRP

24-48 hrs Delivery

24-48 hrs Delivery

International

Delivery

International

Delivery